In today’s fast-paced manufacturing environment, precision is profit. Whether you’re in pharmaceuticals, cosmetics, food & beverage, or chemical production, the right liquid filling machine can dramatically increase efficiency and reduce waste. More importantly, it can boost your bottom line.

Let’s explore how investing in precision liquid filling machines isn’t just a smart operational move—it’s a strategic business decision.

Why Precision Matters in Liquid Filling Machines

Accuracy in a liquid filling machine is not just about neatness. It directly affects cost, customer satisfaction, and regulatory compliance.

Reducing Product Waste

Every milliliter counts—especially when producing high-value liquids like serums, oils, or medicines. A non-precise filling system can overfill or underfill bottles, leading to waste or product rejection. In contrast, precision machines ensure every container gets the exact amount—no more, no less.

Enhancing Brand Reputation

Customers expect consistency. When every bottle is filled uniformly, it reflects professionalism and quality. Conversely, irregular fill levels can make customers question the integrity of your brand. Precision systems build trust through consistency.

How Precision Filling Machines Maximize Profit

Let’s dive into the three primary profit-boosting mechanisms of modern filling technology.

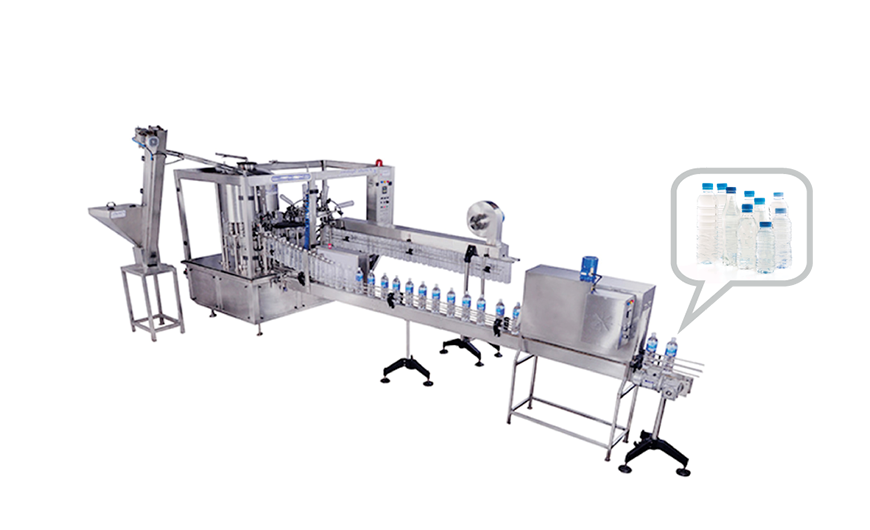

1. Higher Throughput with Less Downtime

Many new-generation liquid filling machines come with automated features such as servo-driven pistons or peristaltic pumps. These machines offer speed without compromising accuracy.

Moreover, they require less frequent calibration and maintenance. That translates to less downtime and more production hours—an equation every manufacturer loves.

2. Reduced Labor Costs

In older filling lines, human intervention was often necessary. Operators had to manually align containers, fill them, and seal them. But now, automated liquid filling machines cut down on manual labor significantly.

Not only do you save on wages, but you also reduce the chances of human error. That’s a dual win.

3. Versatility in Handling Multiple Products

Versatile filling machines can adapt to various container sizes and liquid viscosities. For manufacturers producing different product lines, this flexibility reduces the need to purchase multiple machines.

The result? Lower capital expenditure and quicker transitions between product batches.

Key Features to Look For in a Liquid Filling Machines

Before making an investment, consider these crucial features:

Volumetric or Weight-Based Filling

Depending on your product’s viscosity and sensitivity, you may opt for volumetric (based on volume) or gravimetric (based on weight) filling. Both have their pros and cons, but volumetric systems are generally faster.

Adjustable Nozzles and Anti-Drip Technology

Machines equipped with anti-drip nozzles prevent mess and product loss. Additionally, adjustable nozzles allow seamless switching between different bottle sizes.

Integrated Capping and Labeling Options

Want to streamline your line? Choose machines that offer filling, capping, and labeling in one unit. This consolidation can significantly increase efficiency.

Clean-in-Place (CIP) Functionality

Hygiene is vital in liquid manufacturing. Machines with CIP systems can clean themselves internally without being dismantled. This saves time and ensures compliance with hygiene standards.

Future-Proof Your Business with Smart Filling Systems

The era of smart manufacturing is here. More companies are embracing IoT-enabled machines that allow real-time monitoring, predictive maintenance alerts, and batch-wise data recording.

Benefits of Smart Technology Integration

-

Remote performance monitoring

-

Instant error detection

-

Enhanced quality control

-

Data analytics for efficiency improvements

These intelligent systems enable decision-makers to adjust processes based on data, not guesswork.

Final Thoughts: Invest in Precision, Reap the Profit

Transitioning to precision liquid filling machines is not just a production upgrade—it’s a profit strategy. Reduced waste, faster output, lower labor costs, and better quality control all contribute to greater margins and market competitiveness.

So, whether you’re scaling operations or starting fresh, make your investment count. Choose precision. Choose profit.

Read More: 💸💸😍 Start Your Own Water Liquid Filling Machine Business in Low Investment & Earn 1 Lakh Per Month💸💸