Next-Gen Water Treatment Plants for 2026 High-Demand Industries

Next-Gen Water Treatment Plants are rapidly becoming essential infrastructure for high-demand industries facing rising water consumption, stricter environmental regulations, and increasing operational pressure. From power generation and pharmaceuticals to food processing and manufacturing, industries today require advanced water treatment solutions that deliver reliability, efficiency, and regulatory compliance at scale.

As traditional water treatment systems struggle to manage complex industrial effluents and growing capacity requirements, next-generation water treatment plants offer a smarter and more sustainable approach. By integrating advanced filtration technologies, automation, and real-time monitoring, these systems help industries secure uninterrupted operations while optimizing costs and supporting long-term sustainability goals.

What Are Next-Gen Water Treatment Plants?

Next-Gen Water Treatment Plants are advanced industrial water management systems designed to handle high volumes, complex contaminants, and strict regulatory standards with minimal operational risk.

Unlike traditional treatment plants, next-gen systems combine:

-

Smart automation and AI-driven monitoring

-

Advanced filtration and membrane technologies

-

Energy-efficient treatment processes

-

Modular and scalable designs

-

Real-time data analytics and remote control

These plants are not just about treating water. They are about optimizing performance, reducing costs, and ensuring long-term sustainability.

Why High-Demand Industries Need Next-Gen Solutions

High-demand industries operate under intense pressure. Downtime, water shortages, non-compliance, or inefficiencies can lead to significant financial losses.

Key challenges faced by industries include:

-

Increasing water scarcity

-

Stricter environmental regulations

-

Rising operational and energy costs

-

Higher production volumes

-

Demand for consistent water quality

Next-Gen Water Treatment Plants address all these challenges by offering reliability, adaptability, and intelligence.

Core Technologies Powering Next-Gen Water Treatment Plants

1. Advanced Membrane Filtration

Technologies like reverse osmosis, ultrafiltration, and nanofiltration ensure superior contaminant removal, even for complex industrial effluents.

2. Smart Automation and AI Integration

Automated sensors and AI-based control systems monitor water quality, flow rates, pressure, and chemical dosing in real time, reducing human error and operational risks.

3. Energy-Efficient Treatment Systems

Next-gen plants use low-energy membranes, optimized pumping systems, and energy recovery technologies to cut power consumption significantly.

4. Zero Liquid Discharge Capabilities

Many industries now require ZLD systems to eliminate wastewater discharge, recover usable water, and reduce environmental impact.

5. Modular and Scalable Design

Industries can expand capacity as demand grows without major infrastructure changes, making these plants future-ready.

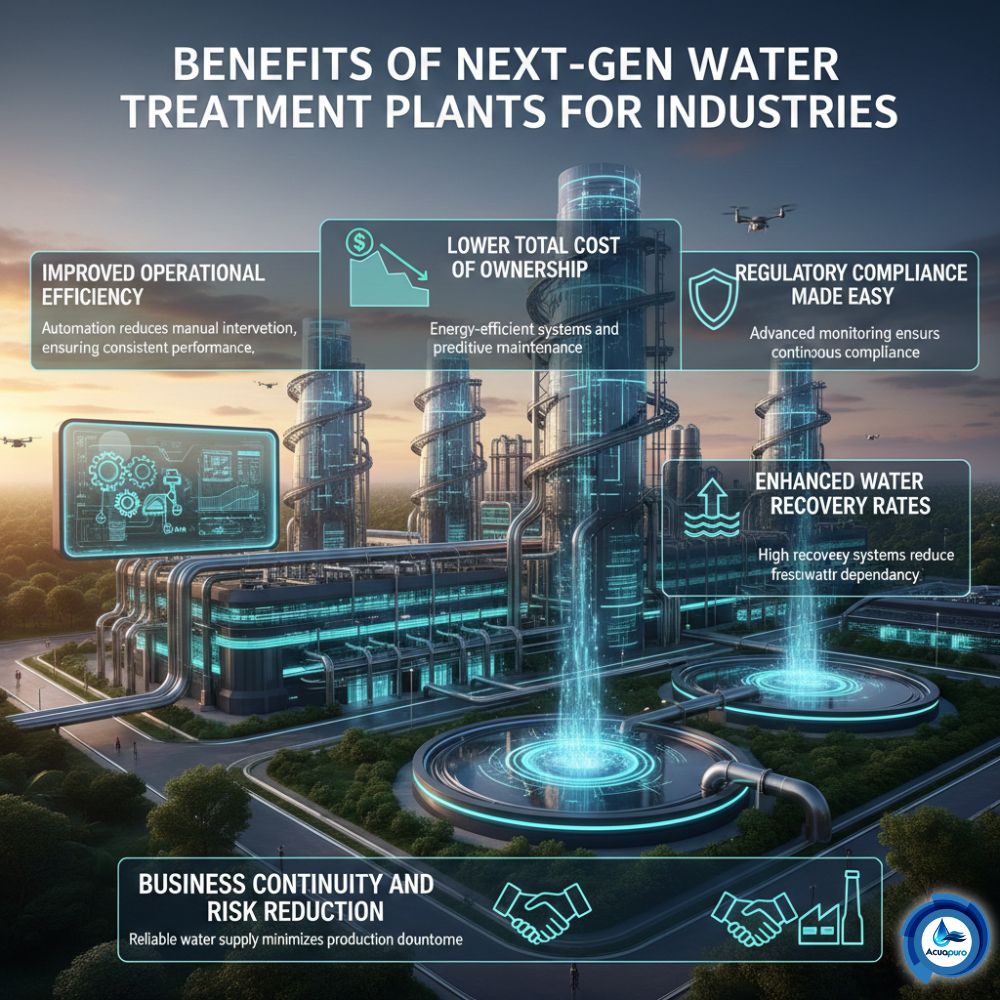

Benefits of Next-Gen Water Treatment Plants for Industries

1. Improved Operational Efficiency

Automation reduces manual intervention, ensuring consistent performance and fewer disruptions.

2. Lower Total Cost of Ownership

Energy-efficient systems and predictive maintenance reduce long-term operating costs.

3. Regulatory Compliance Made Easy

Advanced monitoring ensures continuous compliance with local and global water regulations.

4. Enhanced Water Recovery Rates

High recovery systems reduce freshwater dependency and support sustainable operations.

5. Business Continuity and Risk Reduction

Reliable water supply minimizes production downtime and operational risks.

Industry Applications of Next-Gen Water Treatment Plants

1. Power Generation

Ensures high-purity water for boilers and cooling systems while minimizing water losses.

2. Pharmaceuticals

Maintains ultra-pure water standards required for manufacturing and compliance.

3. Food and Beverage

Delivers consistent water quality essential for hygiene, taste, and safety.

4. Textile and Dyeing Units

Manages complex effluents while enabling water reuse and ZLD compliance.

5. Semiconductor Manufacturing

Supports precision processes requiring extremely low contaminant levels.

Sustainability and ESG Advantages

Sustainability is no longer optional. Investors, regulators, and customers expect responsible water management.

Next-Gen Water Treatment Plants support ESG goals by:

-

Reducing freshwater consumption

-

Minimizing wastewater discharge

-

Lowering carbon footprint

-

Supporting circular water use

This makes them a strategic investment, not just a compliance requirement.

How Next-Gen Water Treatment Plants Drive ROI

Industries adopting next-gen systems experience:

-

Reduced water procurement costs

-

Lower energy bills

-

Fewer regulatory penalties

-

Increased production uptime

-

Stronger brand reputation

Over time, these benefits translate into measurable financial returns and competitive advantage.

Choosing the Right Next-Gen Water Treatment Partner

When investing in next-gen technology, industries should look for:

-

Proven industrial experience

-

Custom-designed solutions

-

Strong after-sales support

-

Remote monitoring capabilities

-

Compliance expertise

The right partner ensures that the system delivers long-term value, not just short-term results.

Future Trends in Industrial Water Treatment

The future of industrial water treatment includes:

-

AI-driven predictive maintenance

-

Digital twins for plant optimization

-

Increased water reuse mandates

-

Fully autonomous treatment plants

-

Integration with smart factories

Next-Gen Water Treatment Plants are at the center of this transformation.

Next-Gen Water Treatment Plants Powering Industry Growth: Final Thoughts

For new businesses, every decision sets the foundation for future success. Investing early in the right equipment can eliminate production bottlenecks, improve product quality, and unlock growth opportunities. The liquid filling machines business offers startups a reliable, scalable, and cost effective path to professional manufacturing.

Whether you are launching a food brand, cosmetic line, pharmaceutical product, or chemical solution, liquid filling machines provide the efficiency and consistency needed to compete in today’s fast moving markets.

Read More: हाई-डिमांड इंडस्ट्रीज़ के लिए नेक्स्ट-जेन वाटर ट्रीटमेंट प्लांट्स: स्मार्ट इन्वेस्टमेंट 🤑💸